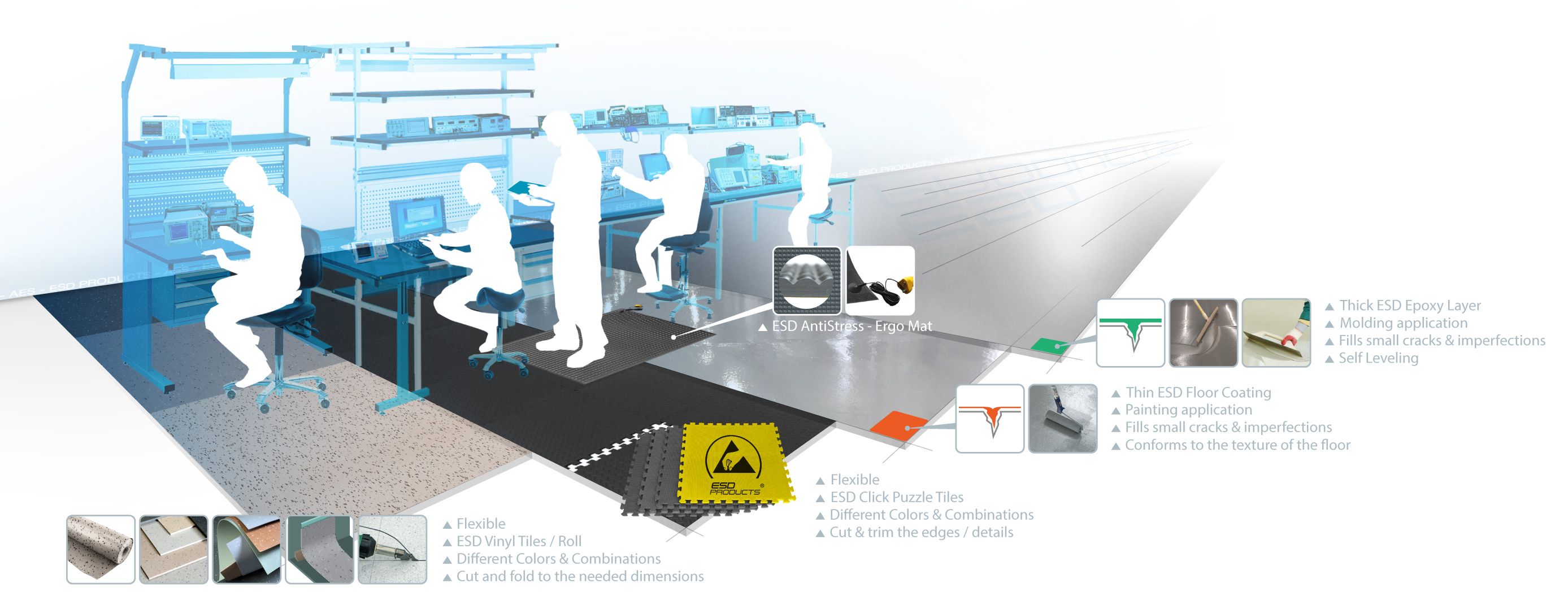

ESD Flooring

ESD Flooring Static Protective | Semi Conductive Floor |

IEC - International Electrotechnical Commission

The principal cause of static electricity is frequently cited as the movement of people and materials in the work environment. This routine movement, particularly the contact and separation of shoe from floor, generates charges as high as several thousand volts. Similarly, the movement of mobile carts or other equipment will generate electrostatic charge. This subclause will review the use of floor materials to dissipate electrostatic charge. It will cover floor coverings, floor finishes, topical anti-stats, floor mats, paints and coatings.

Static protective floor materials are used in the electronics industry for:

- Grounding of personnel (floor materials can be used in combination with static control footwear as either a primary ground or a secondary, backup system, ground for wrist straps in critical ESD processes)

- Grounding of ESD control items such as:

- mobile carts

- ergonomic stands used to raise the product to an employee’s working height

- workstations

Floor coverings, mats, paints and coatings help control static charge by providing a path of moderate electrical conductivity from the human body or ESD control item to ground. Many flooring products use a conductive material, such as carbon, metal or other additives, that extends from the surface of the material to an underlying substrate such as conductive adhesive. The floor material is then connected directly to ground.

Floor finishes and topical anti-stats, on the other hand, function by two separate mechanisms.

First, they reduce the surface's tendency to generate a static charge. Second, they provide a path for the dissipation of charge. If the floor finish or topical anti-stat is used for primary grounding they shall be able to limit charging while dissipating it to ground.