The AWP line is probably the best solution known in the world for the fully automatic processing of power cables (cords).

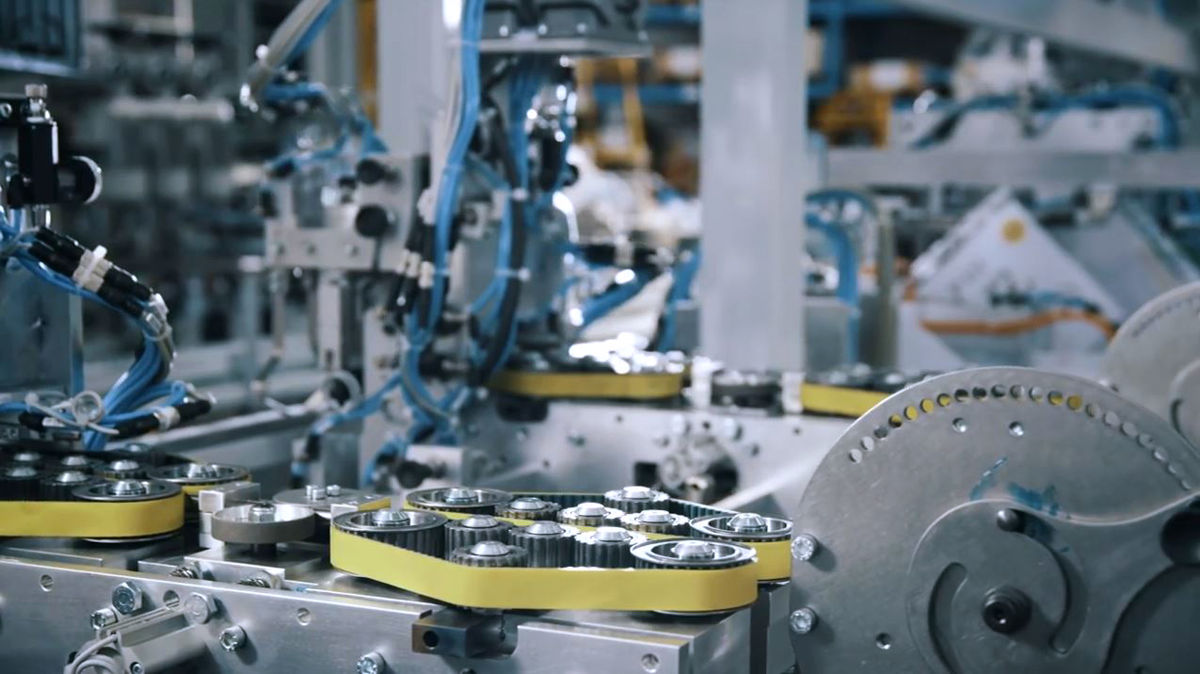

The typical processing steps are as follows:

- Automatic or manual cable power supply

- Cut to size

- 1st side stripping and stripping of the conductors

- Insert crimping on the 1st side with CFM Control

- 2nd side stripping and stripping of conductors

- Insert or terminals on the 2nd side crimping with CFM Control

- Electrical Test

- Discharge of the power cord

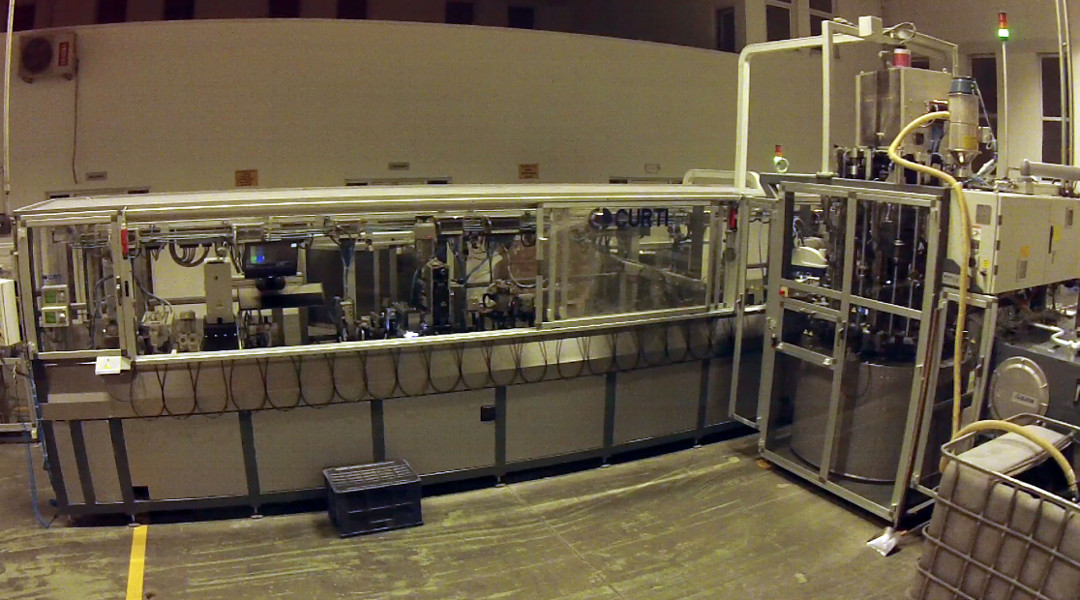

Furthermore, the AWP line is designed to be connected to the injection rotary press Rotary Moulding (CURTI patent), thanks to which it is also able to carry out the moulding operation, and then produce a 100% finished component, mechanically and electrically tested. The total absence of manual processes within the entire manufacturing process excludes the possibility of human error, allowing for an unmatched degree of quality and performance.