Miniapplicators

KM Corporate

A product adaptable to all units crimping, manual and automatic and customizable for any terminal required.

Download Catalog

Characteristics

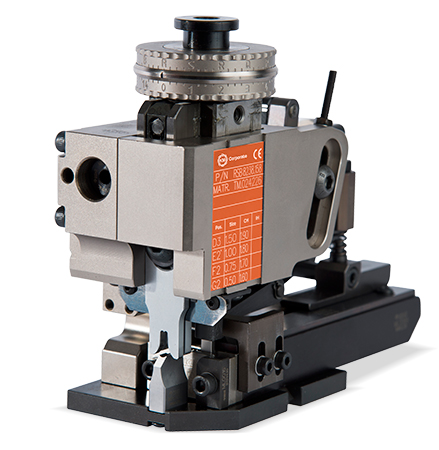

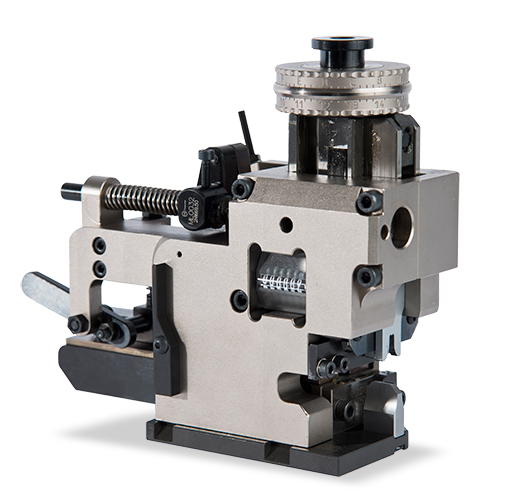

Many years of experience in manufacturing of crimp applicators has led to a high quality and high technological product. Accurate choice of materials and attention to working and treatment processes of all parts of a crimp applicator make this product long lasting and reliable. The construction concept is a product adaptable to every manual and automatic crimp units available in the market and easy to customise for any requested terminal.

Our basic version includes the 4-position head for height adjustment.

Each crimp applicator is delivered complete with instructions handbook saved on pen drive and crimped samples done during the factory acceptance test.

REF. CRIMP APPLICATOR – MODEL TME1

Crimp applicator for end feed terminals.

REF. CRIMP APPLICATOR – MODEL TMS1

Side feed applicator with standard feeding left/right.

REF. CRIMP APPLICATOR – MODEL TMS4

Side feed applicator with feeding left/right.

CRIMP APPLICATOR KSP SPLICE – MODEL TMG1

This special applicator model has been specifically made for parallel and junctions connections.

PNEUMATIC CRIMP APPLICATOR – MODEL TMHP1

This model has been specifically made for working PREINSULATED articles, for big terminals and for applications where a smooth, optimized management of the articles’ feeding is needed.

Feeding is done by means of a pneumatic cylinder mounted on the applicator and acting directly on the feeding of the terminals. The overall dimensions make this applicator universal and adaptable to all commercial crimping units. As for the other models, materials and treatments are accurately chosen to maintain a high quality level and reliability for a long time.

PNEUMATIC CRIMP APPLICATOR FOR FERRULES – MODEL TMFP1

This model has been specifically made for working FERRULES for terminals of type WIRE-END SLEEVE to be fed arranged in chain on carrier. Feeding is done by means of a pneumatic cylinder mounted on the applicator and acting directly on the feeding motion of the terminals. The applicator is equipped with a window-type centring system for facilitating the insertion and positioning of the wire to be crimped.

4-POINT APPLICATOR – MODEL TMT1

This model has been made to perform 4-point crimping on TURNED bulk articles. Loading of the articles is performed by hand and crimping is obtained by means of concentric movement of closing punches. It allows to work several articles on the same tool by simply replacing the sleeve used for insertion of the article.

DOUBLE-APPLICATOR FOR SIMULTANEOUS CRIMPING – MODEL TMSE5

This model can process and crimp two identical articles simultaneously. The applicator may be either mechanical or pneumatic version depending on the article to process.

APPLICATOR FOR THERMAL PROTECTORS – MODEL TMTP10

This model has been specifically made for working and crimping of thermal protectors. Loading of the thermal protector is performed by hand.

Model TMP10 may be combined with a crimping unit model KM1110 equipped with vibration feeder in order to perform the process automatically.

APPLICATOR FOR IDC CONNECTORS – MODEL TMC1 / TMCP1

For working of IDC connectors we can offer customised solutions based on customer’s requirements and type of connector.

The applicator may be delivered either as mechanical or pneumatic version.

APPLICATOR FOR TWIN CABLE

This model is specific for working of flat cable as well as for closing the connector at the cable’s ends and at an intermediate position.

APPLICATOR FOR MEDICAL NEEDLES

This is a special applicator for the medical sector that performs both, the incision on the article and the crimping of the signal wire.

TOOL-LESS APPLICATOR MODEL TMTRD005

This applicator consists only of a standard body, without any part for crimping and/or cutting-out. The applicator can be customised according to working requirements.

AVAILABLE OPTIONS

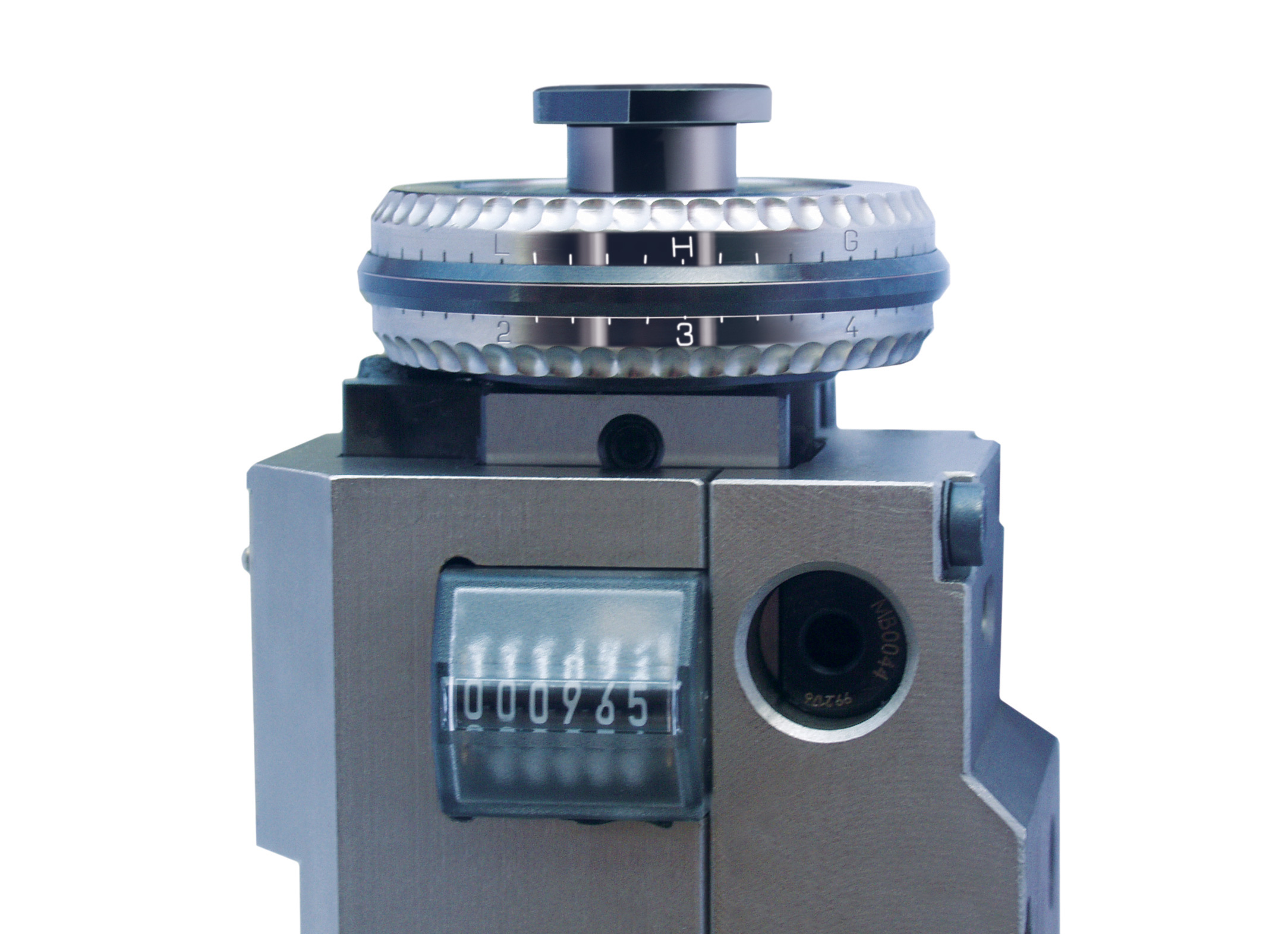

MICROMETRIC WHEEL

This micrometric device is composed of two overlapped ring nuts and a shared reference index. The upper ring nut, distinguished by a series of letters, allows the adjustment of the pressure on the conductor whilst the second ring nut, distinguished by a series of numbers, allows the adjustment of the pressure on the insulation. At every turn both ring nuts perform the minimum incremental displacement 0.02 mm. The advantage of this system is to offer immediate reading of the indexes and the possibility to discriminate different types of insulation – at equal cross section of the conductor (for ex. Standard, Phase 3 etc.). This applicator allows, additionally, to avoid any intervention on crimping units having different Shut-Height values.

It is also possible to exchange the micrometric device with the basic version -the graduated wheel- without need to intervene on other parts of the applicator’s assembly.

COUNTER

Upon request, all applicator types can be delivered equipped with non-resettable counter to allow monitoring the useful life of components and programme the substitution of the applicator’s crimping tools.