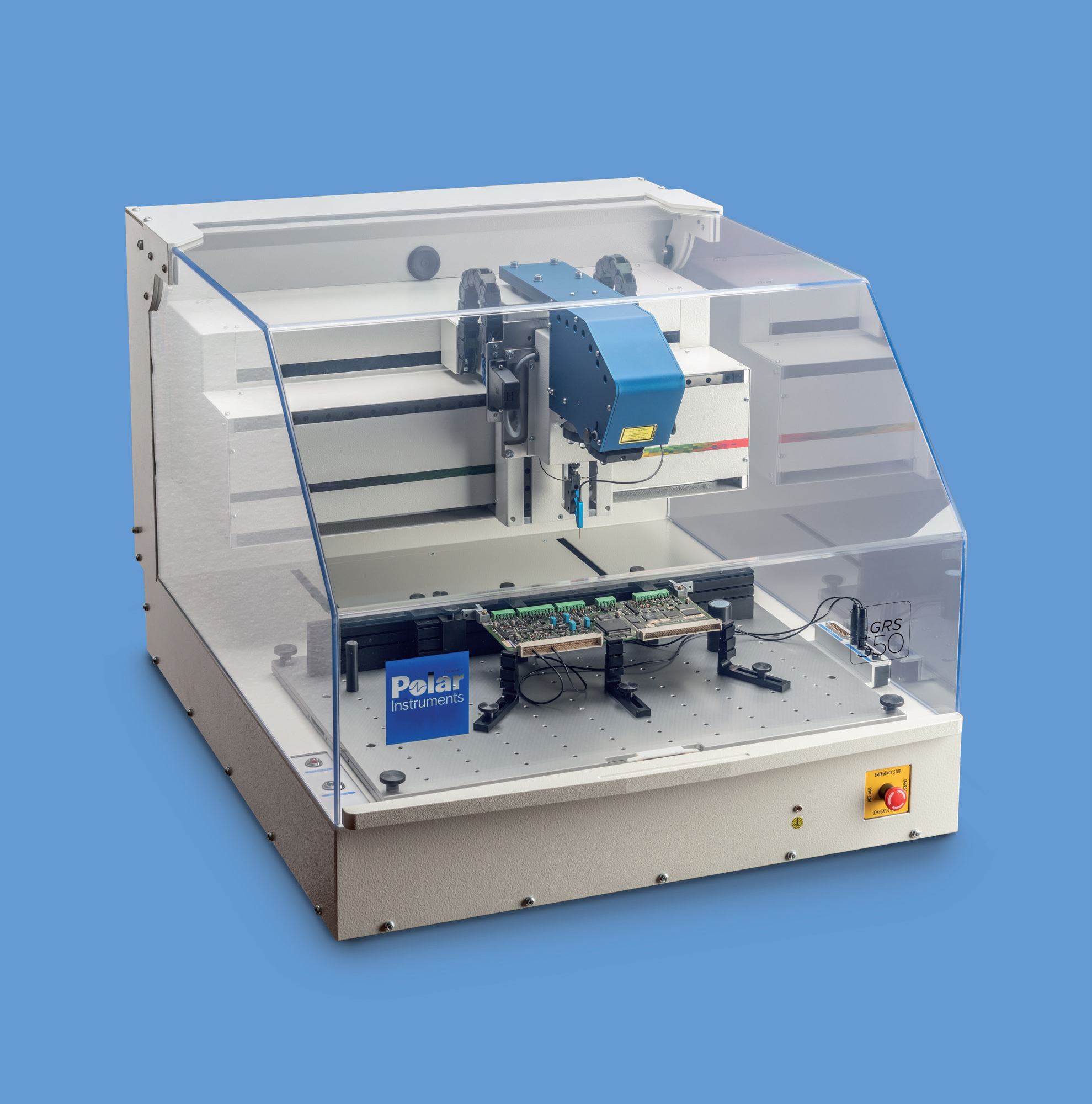

Flying Probe PCB repair system GRS550

Polar

Automatic troubleshooting on complex circuit boards

Download Catalog Watch Video

Its predecessor, the GRS500, set standards in the electronics industry with its high level of testing depth, economy and ease of use. The new GRS550 offers the tried and tested operating concept, but a completely new drive technology with higher travel speed and positioning accuracy .

Rapid error analysis on assembled assemblies

Failure analysis on complex electronic assemblies is not an easy task. The GRS was developed to enable faults to be localized quickly and thus to use your valuable time efficiently to get a defective assembly back to work. You save time, money and maximize your production yield.

Prototypes, small series and new product launches represent a challenge in electronics manufacturing .

How do you ensure that both the test program and the test adapters are available on time when a new product is launched? The new Polar GRS550 is designed to help you. The system is used for fault diagnosis in the following areas: prototype construction, new product launches, small series, for which a traditional in-circuit test is too expensive. The system offers extensive test options with short preparation times and low costs. The key to this is the extensive use of CAD data in combination with proven fault diagnosis technology. When series production starts, the system provides indispensable support after the function test and enables maximum production yields.

Error diagnosis on assemblies with the GRS550

The system is particularly suitable for fault diagnosis on assemblies for which an adapter-based test is not an economical solution. The GRS550 compares the characteristics of a sample assembly with the defective boards by means of node impedance analysis and a video image display, which enables the direct comparison of high-resolution images of the good assembly and the test item. A powerful CAD-based repair software enables faults to be tracked quickly on the faulty network.

A versatile contact and inspection system

The GRS550 system can be used on all component technologies and offers the following functions:

• A flight height of 100mm for "flying over" high components.

• Two live video cameras

• One camera for programming and inspection

• One camera for live monitoring of the contact position

The GRS550 enables fault diagnosis on all component technologies - from SMT, PTH to BGA, whereby the system automatically positions the test points on the accessible points of the networks.

The cost advantage

The system was designed for long life, flexibility and low operating costs. This means that you can drastically reduce your test costs over many years and cover a wide variety of assemblies.